In This Issue...

News

- Tester Retread - Digital hydraulic motion control overhauls legacy tire testing system

- How is technology democratization impacting industrial automation?

Distributor Highlight

People at Delta

Tech Tip

- Applying the Noise Error Rate

Upcoming Trade Shows & Conferences

Opportunities at Delta

Learning More About Delta

- Education & Training

- Useful Links

|

|

|

Tester Retread - Digital hydraulic motion control overhauls legacy tire testing system

by David McNichol in Design Engineering

"Tires may be among the most ordinary of daily items, but their quality control remains paramount. Billions of people depend on tire integrity for their daily personal safety, and the tire market only reflects a growing need for product reliability. Testing and consultation firm, Smithers, pegged the global tire market at $261 billion by 2021, on track to exceed $325 billion by 2026. This is a huge industry, and it depends on reliable, accurate testing among manufacturers.

Much of this testing hinges on a few key devices, one of which is a tire plunger machine, such as the Model 70 from RJS Corp. With roots in the tire testing business dating back to the 1950s, RJS now has equipment placed in roughly 90% of the tire factories worldwide."

|

|

|

How is technology democratization impacting industrial automation?

by Anna Townshend in Control Design

"A Control Design reader writes: Technology suppliers are continually offering automation components that are easier to integrate and install, and many markets these plug-and-play products as a solution to the growing worker shortage. Who in the industry is asking for these types of solutions—machine builders, system integrators or end users? All of the above? Is this trend industry-led or industry-specific? As an automation engineer for a machine builder, we do have trouble finding young talent, but I worry that the democratization of automation technology might still put me out of a job someday. I think the idea is to use our engineering talent for more important work, but, as a manager, I would still be uncomfortable with less-qualified people working on our machines. What am I missing here? Should I be thinking about this differently or thinking about managing our engineering talent differently?"

Jacob Paso, Delta Motion's Product Development Manager, writes:

"This trend of plug-and-play automation products might be cast more precisely as natural product evolution. As time marches along, the forces of competition inevitably lead to products and processes that are easier to implement and use.

The goal of easing the integration of devices into control systems is to take away the busy work of controls integration. Hopefully, engineers’ time is not consumed by mundane tasks of trying to get Box A to connect to Box B, which will in turn pass data to a device. The engineer should be free to concentrate on building an elegant, robust and effective control design. The aim should be to allow humans to do what they do best, apply creativity to technical problems, and not have to worry about the repetitive work of connecting a series of devices together and making them communicate.

Even with plug-and-play products, you will always need highly skilled engineers to understand the machine and choose the best components, whether they be plug-and-play components or a more specialized combination of products, all depending on the needs of the machine, the customers and the market competition.

Continue focusing on hiring top-notch engineers. If plug-and-play components allow some portions of the job to become streamlined enough that they do not require advanced engineers, you may be able to fill some roles with technicians. In any case, you will always need some top engineering talent so that your machines maintain an edge in the marketplace, whether that edge is features, pricing or both. If you don’t, competitors will step in and do it."

|

|

|

Distributor Highlight

AirHydroPower of Louisville, KY, is Delta Motion's distributor serving customers in Northern Kentucky and Southern Indiana. AHP has a long history of hydraulic service and support since its founding in 1961. In addition to the standard hydraulics offerings like hoses, fittings, piping, filters, and fluids through their Parker Stores, AHP also offers value added services for material handling and electrical and hydraulic automation services. AHP's Engineered Solutions team provides customers with complete motion control solutions. Other services include machine vision, automatic product labeling solutions, and machine safety equipment.

A big thank you to the team at AHP for their support of Delta, congratulations on over 60 years of business success and customer support, and we look forward to continued growth in the future!

|

|

|

People at Delta

Mike Dodds, Pacific Northwest and Western Canada Regional Sales Manager

Delta Motion is pleased to announce the addition of Mike Dodds, Regional Sales Manager, to our team. Mike is managing Washington, Oregon, Idaho, Montana, and the Western Canadian provinces. Since joining Delta in April, he has been getting acquainted with the distributors in the region and learning about the projects and industries served.

Mike brings a wealth of integration experience to Delta , especially in the aerospace manufacturing industry. He has integrated RMC motion controllers in numerous projects and understands the challenges that system integrators face while getting a system to perform to specification in tight time schedules. Mike is focused on helping the distributors he supports to become even more skilled integrating RMC controllers to assist our mutual customers in achieving outstanding system performance.

All of us at Delta are very happy to welcome Mike to our team. We hope that many of you have the opportunity to meet and work with Mike during the coming year.

|

|

|

Tech Tip

Applying the Noise Error Rate

by Sean O'Banion

The Noise Error Rate setting can help reduce unwanted spikes in feedback from translating into unwanted spikes in motion control when utilizing noisy feedback signals. It does this by filtering out short, sudden increases in velocity feedback, such as shown in Fig. 1. When this noise exceeds a set threshold for less than three consecutive loop times the RMC will temporarily estimate the motion target to maintain smooth motion. If the velocity noise exceeds the threshold value for three or more consecutive loop times, a halt is triggered.

Fig. 1 - Example of position feedback noise

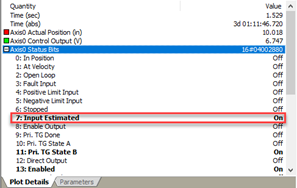

The Noise Error Rate should be set to a value much greater than the max expected velocity of the project to avoid triggering a Noise Error Halt during normal movement (Fig. 2). During motion, if the Noise Error Rate is exceeded and the position is being estimated by the RMC the Input Estimated Status Bit will turn on (Fig. 3).

Fig. 2 - Noise Error Rate setting

Fig. 3 - Input Estimated status bit

Fig. 3 - Input Estimated status bit

If the Noise Error Rate threshold value is exceeded for three or more loop times the Noise Error Bit will be set and a Halt is triggered. The Halt behavior is set in the Halts - Auto Stop Configuration menu.

|

|

|

Tradeshows & Conferences

Upcoming Trade Shows

Please check Delta's Trade Shows page regularly for updates. Here are the upcoming shows we will be attending in the 2nd Quarter of 2023. We hope to see you; come and say hello at our booth!

Automotive Testing Expo China

Forest Products Machinery & Equipment Expo

FABTECH

Automotive Testing Expo USA

PTC Asia

|

|

|

Opportunities at Delta

Electronics Design Engineer

Delta is seeking an excellent Electrical Engineer to join our team. The ideal candidate will have relevant experience with analog and digital circuit design, PCB layout, and FPGA programming. This is a great opportunity for the right individual to join Delta's team developing and supporting our industry-leading motion control products. A complete opening description can be found by following the link.

|

|

|

Learning More About Delta

Education & Training

Delta's in-person Classroom Training is a fantastic way to learn RMCTools software and how to configure and program RMC controllers. Self-Paced, Live Online, and Custom training courses are also available depending on your needs. Please check Delta's Internet Training page frequently for schedule updates and added classes. You may also contact Delta by phone at (360) 254-8688, at technicalsales@deltamotion.com, or reach out to your Regional Sales Manager.

|

|

Self-Paced Learning

Delta also offers self-paced training options, as well.

- Video Tutorials An easy way to get up to speed on the RMC's features with easy to follow video guides.

- Online RMCs Try RMCTools or custom RMCLink programs when you don't have a physical RMC to test with.

|

|

Discussion Forum

Delta's Discussion Forum is a place for users to share ideas about User Programs, unique applications, or third-party equipment that works well with the Delta RMC Motion Controllers.

|

|

Distributor Only Website

If you are a Delta distributor and need a password or user ID, email us or call Delta at (360)-254-8688.

|

|

Delta Computer Systems, Inc.

1818 SE 17th St. - Battle Ground, WA USA 98604-8579

P: 360-254-8688 - F: 360-254-5435

Delta Motion Ltd.

5 South Charlotte Street - Edinburgh, EH2 4AN, United Kingdom

P: (+44) 0131 447 7924

|

|

|

|