In This Issue...

News

- How to Handle Heavy Lifting - Control Design

- Complex Math, But a Simple Solution - Hydraulics & Pneumatics

- Sizing Accumulators for Arbitrary Moves - Hydraulics & Pneumatics

- Delta Webinars

Distributor Highlight

People at Delta

- Sean O'Banion, Applications Engineer

Tech Tip

Trade Shows & Conferences

Learning More About Delta

- Education & Training

- Useful Links

|

|

|

How to handle heavy lifting

Flexible hydraulic/electric motion control brings demanding die/mold cart design to completion

by Mike Birschbach

"Located in Mt. Zion, Illinois, Green Valley Manufacturing has been making die and mold handling equipment for nearly 25 years. Die or mold carts don’t seem glamorous at first. Functionally, they are cousins to forklifts, but these carts specialize in moving awkwardly sized and sometimes very heavy dies or injection molds, some exceeding 100,000 lb, from one point to another with exceptional speed and stability. Client industries for Green Valley’s carts span from aerospace and automotive to medical and military. Practically every job is in some way a custom order.

A tier-one passenger vehicle parts manufacturer approached Green Valley in 2019 with a novel challenge. The client wanted a mold cart capable of lifting 70,000 lb. Moreover, because of the tight spaces in the manufacturing environment, they needed the cart built with four-wheel drive, four-wheel steering and an extremely precise four-cylinder lifting system. The client wanted Ackerman steering to increase tire traction, steering range and precision when executing turns. Essentially, the cart needed the ability to turn on a dime as well as crabwalk sideways by turning all of the wheels in the same lateral direction. The cart required four different steering modes—an impossibility with conventional mechanical linkage.

|

|

Sizing Accumulators and HPUs for a Cylinder’s Sinusoidal Motion

The math might be complex, but it‘s straightforward.

by Peter Nachtwey

"Sizing the hydraulic power unit (HPU) and accumulator needed for a cylinder’s sinusoidal motion is easy. Three formulas define the parameters: one for the HPU, two for accumulator. It is interesting how these formulas are derived and what they reveal. (If you don’t like math, skip to the end for a summary).

Sinusoidal motion requires a sine function that calculate the position for the target generator. The sine function returns values from −1 to 1 as a function of time."

|

|

Sizing Accumulators for Arbitrary Moves

Here are some straightforward methods of determining how large an accumulator is needed for a given motion profile.

by Peter Nachtwey

"Several different technologies can be used to store energy in accumulators: weighted pistons, bladders (or diaphragms), springs and the commonly used hydro-pneumatics. Accumulators use that energy to keep system pressure relatively constant or to put oil under pressure for low duty cycle actuators. In a previous article, I mentioned that hydro-pneumatic accumulators should be pre-charged to about 90% of the system pressure, typically with nitrogen. This ensures the accumulator contains mostly nitrogen and just enough oil to keep the accumulator from being completely empty. While calculating the pre-charge pressure was a difficult problem, figuring out how big the accumulator must be is a challenge."

|

|

Delta Webinars

Our webinar program has been well received since beginning in April, and our Applications Engineering team is grateful for all of the folks who are willing to take an hour out of their day to join us on line. Here are the three webinars from July, August, and September.

|

|

|

|

|

July

Presented by Delta Application Engineer David McNichol for GCC, this webinar is a good introduction to high speed, high precision hydraulics through closed-loop electronic control.

|

|

|

|

August

Delta's Motion Product Development Manager Jacob Paso demonstrates how to configure communications between several popular PLC brands and RMC motion controllers. Jacob shows some features of the RMCTools software that help accelerate the setup and how to read and write variables to the controller.

|

|

|

|

September

Jacob Paso, Product Development Manager for Delta, shows how to connect and configure HMIs from a few different manufacturers to communicate with RMC motion controllers.

|

|

|

The link below will take you to the Webinars page on deltamotion.com, where you can play recordings of all of the webinar sessions. Upcoming sessions will also be linked on that page, so check back frequently for upcoming topics and links for registering.

|

|

Distributor Highlight

tsb-bescom

We frequently feature long-time Delta distributors in our newsletter - this time it is a nice change to discuss our newest distributor! tsb-bescom of Duiven is Delta's authorized distributor for customers in the Netherlands and Belgium. tsb is more than just a "box seller" of industrial automation equipment and sensors. Rather, tsb's engineers and technical sales staff offer design and assembly assistance, resulting in a design that exceeds the customer's expectations. Their expertise and product offerings support several specific markets and applications including marine and offshore, renewable energy, food, packaging, metals processing, and rail transportation.

Value adding distributors such as tsb-bescom are a key component to Delta's development in global markets, and we are happy to welcome tsb to our distributor group. You can visit their website and see their product offerings with the link below. Welcome tsb-bescom!

|

|

|

People at Delta

Sean O'Banion - Applications Engineer

|

|

|

We are pleased to welcome Sean O’Banion to the Applications Engineering team here at Delta. Applications Engineering is a key component of Delta’s commitment to 24/7/365 support so we are always excited to find talented, personable engineers who can help our customers. Sean certainly fits that description.

Sean holds a BSEE degree from WSU Vancouver, as well as AA and AS degrees from Clark College. His focused area of study was on embedded systems, field-programmable gate arrays (FPGAs), and renewable energy, which provide an excellent background to his role supporting Delta customers using RMC motion controllers. A self-described “fixer” in his free time, Sean enjoys repairing or tinkering with electronics, motorcycles, snowboards; or as he puts it, “finding ways to go faster.”

Sean is also studying the RMCTools software, so that he can be one of our team of trainers at Delta. If at some point in the future you take one of our Training classes, there is a good possibility that Sean will be teaching the course.

|

|

|

Tech Tip

The Capture feature

by Sean O'Banion, Applications Engineer

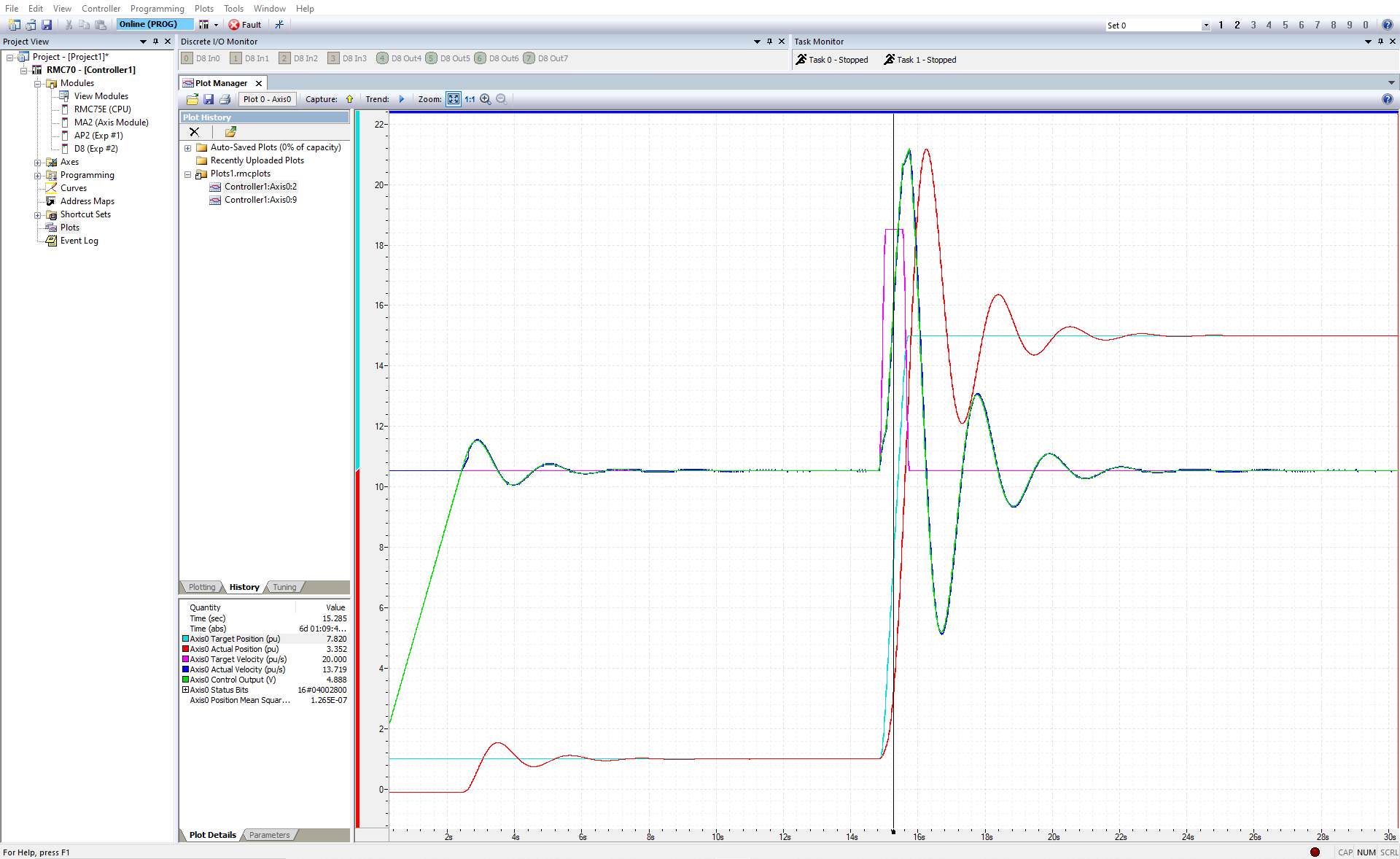

This is one of the very common but potentially overlooked features of the Plot Manager. In particular, Capture is very useful when trying to troubleshoot or isolate a problem behavior on an axis. Usually we are interested in watching system motion over time using the Trend feature, like the example below.

|

|

|

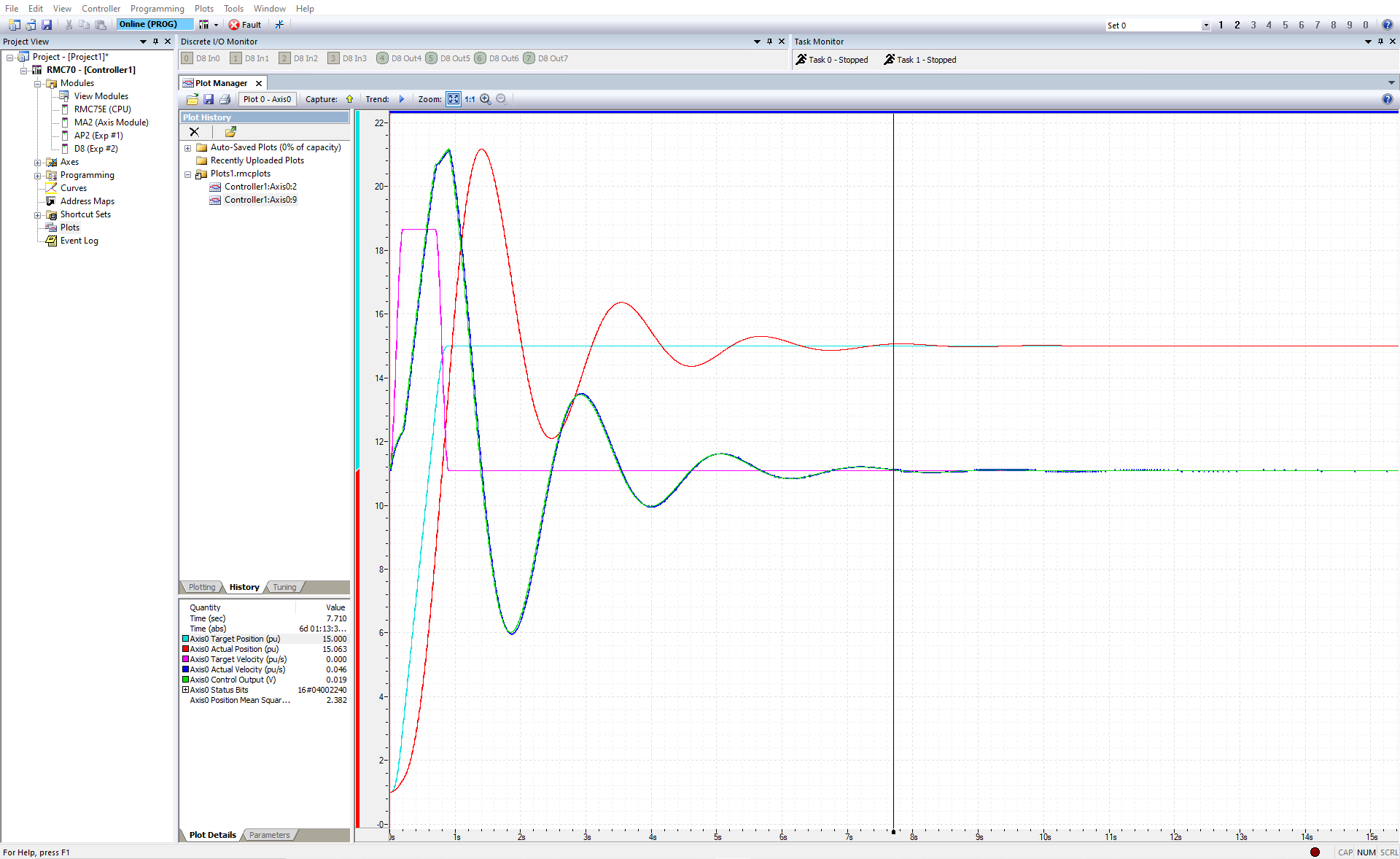

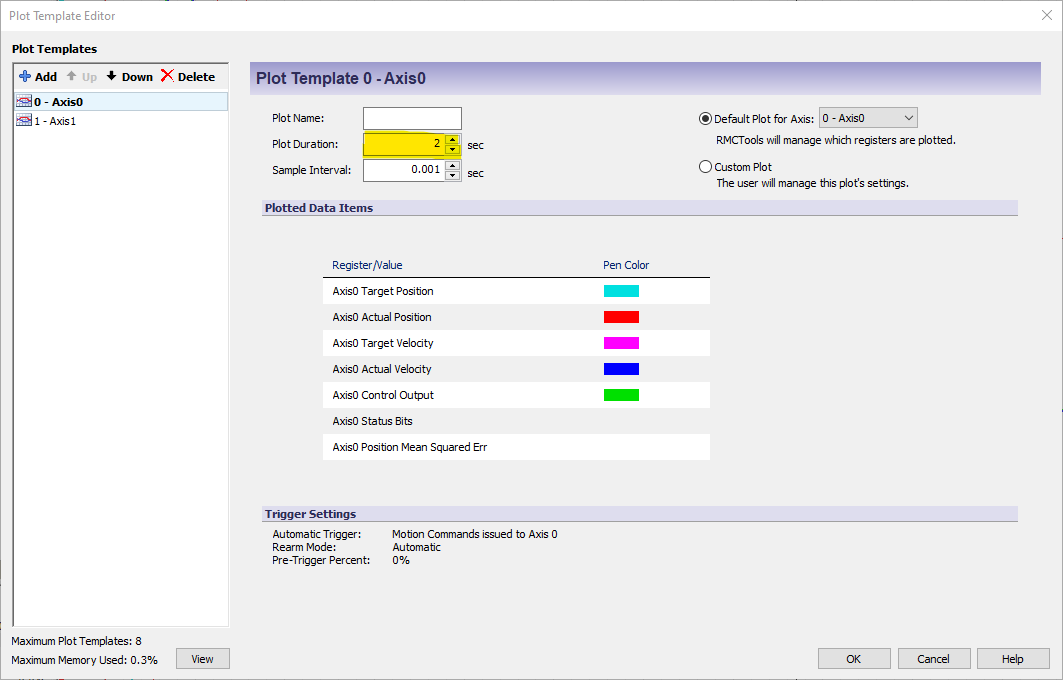

But if you are trying to look at a specific reaction to a command, the Trend feature might not be the easiest method to use. You can certainly adjust the Plot Template to look at the data you are interested in, prepare the command, start the Trend, and then issue the command. Once the move has happened or the behavior you are interested in has occurred, you can stop the Trend. The Capture feature is a shorter way to accomplish the same task.

You can set up the Plot Template to focus just on the data you need, or use the Template defaults. Generally the default selections will contain most of the information needed, but may have extra data that fill the plot and mask what you are trying to see. Prepare the command as usual, but now just issue the command. Switch to the Plot Manger and click the  Capture button, and a plot of the move or system behavior will be displayed. The default plot time can be changed in the Plot Manager settings. Capture button, and a plot of the move or system behavior will be displayed. The default plot time can be changed in the Plot Manager settings.

This feature allows you to focus on what the axis or axes are doing without having to constantly stop a Trending plot and trim it to look at what you're interested in. A nice shortcut that helps make troubleshooting easier!

|

|

|

Tradeshows & Conferences

Upcoming Trade Shows

With the worldwide COVID-19 outbreak, the trade show outlook is uncertain. All of Delta's tradeshows have been cancelled for the remainder of 2020. Please check Delta's Trade Shows page in early 2021 for our anticipated trade show schedule for the coming year.

|

|

Learning More About Delta

Education & Training

Delta's in-person Classroom Training is now being offered again, following Washington State guidelines for personal protection and social distancing. Self-Paced, Live Online, and Custom trainings are being offered as usual. Please check Delta's Internet Training page frequently for schedule updates and added classes. You may also contact Delta by phone at (360) 254-8688, at technicalsales@deltamotion.com, or reach out to your Regional Sales Manager.

|

|

Self-Paced Learning

Delta also offers self-paced training options, as well.

- Video Tutorials An easy way to get up to speed on the RMC's features with easy to follow video guides.

- Online RMCs Try RMCTools or custom RMCLink programs when you don't have a physical RMC to test with.

|

|

Discussion Forum

Delta's Discussion Forum is a place for users to share ideas about User Programs, unique applications, or third-party equipment that works well with the Delta RMC Motion Controllers.

|

|

Distributor Only Website

If you are a Delta distributor and need a password or user ID, email us or call Delta at (360)-254-8688.

|

|

Delta Computer Systems, Inc. © 2020 Delta Computer Systems, Inc. © 2020

1818 SE 17th St. - Battle Ground, WA USA 98604-8579

P: 360-254-8688 - F: 360-254-5435

Delta Motion Ltd.

101 Rose Street South Lane - Edinburgh, EH2 3JG, United Kingdom

P: (+44) 0131 447 7924

|

|

|

|