In This Issue...

News

- Delta Offices Open Under State Guidelines

- Delta Webinars

- Multi-Axis Motion Controller Accelerates Gear Testing - Quality Magazine

- How to Handle Heavy Lifting - Control Design

- Peter Nachtwey Named to IFPS Hall of Fame Class of 2020

- Motion Control Feature - Hydraulics & Pneumatics

Distributor Highlight

People at Delta

- Sam Juvonen, Business Systems Manager

Company News

- Lunchbox Sessions with Fluid Power World and Carl Dyke, sponsored by Delta Computer Systems

Tech Tip

- RMCTool Plot Auto-Save feature

Trade Shows & Conferences

Learning More About Delta

- Education & Training

- Useful Links

|

|

|

|

Delta Offices Open Under State Guidelines

Delta Computer System’s Battle Ground offices are open during normal business hours, following Washington State guidelines. Delta Support & Regional Sales Managers continue to be available by phone or email, as usual.

When visiting Delta, we will ask you to follow Washington State guidelines to prevent the potential spread of the COVID-19 virus. Thank you for your assistance and your continued patronage, and please feel free to contact us if you have any questions.

|

|

|

|

Two of Delta's Application & Support Engineers, Jacob Paso and David McNichol, have taken the opportunity during the COVID-19 quarantine to produce and present webinars during the months of April, May, and June. Each of these webinars run approximately one hour, and feature live hydraulic lab systems here at Delta running on camera! These webinars cover different motion control applications, such as testing and presses, as well as demonstrating tuning and troubleshooting techniques.

The link below will take you to the Webinars page on deltamotion.com, where you can play recordings of all of the webinar sessions. Upcoming sessions will also be linked on that page, so check back frequently for scheduled webinars.

|

|

Multi-Axis Motion Controller Accelerates Gear Testing

by Reid Bollinger

"Materials testing and characterization is often a lengthy process. It can take more than a year and billions of testing cycles for a manufacturer to characterize the properties of a new metal alloy to be used in a critical application, such as a component of an automotive or jet engine. Typically, the testing regimen is prescribed by an OEM in accordance with procedures specified in industry organization standards. For example, one testing method for bending fatigue of gear steels is outlined in SAE Standard 1619 using a standard fixture and standard gear design. Companies manufacturing automotive and aerospace engines often refer to this and other standards as they specify the materials and designs of gears to be used in their applications, as do companies manufacturing test systems that verify production gears meet the standards."

Quality Magazine, April 2020

|

|

|

How to handle heavy lifting

by Mike Birschbach

"Located in Mt. Zion, Illinois, Green Valley Manufacturing has been making die and mold handling equipment for nearly 25 years. Die or mold carts don’t seem glamorous at first. Functionally, they are cousins to forklifts, but these carts specialize in moving awkwardly sized and sometimes very heavy dies or injection molds, some exceeding 100,000 lb, from one point to another with exceptional speed and stability. Client industries for Green Valley’s carts span from aerospace and automotive to medical and military. Practically every job is in some way a custom order.

A tier-one passenger vehicle parts manufacturer approached Green Valley in 2019 with a novel challenge. The client wanted a mold cart capable of lifting 70,000 lb. Moreover, because of the tight spaces in the manufacturing environment, they needed the cart built with four-wheel drive, four-wheel steering and an extremely precise four-cylinder lifting system. The client wanted Ackerman steering to increase tire traction, steering range and precision when executing turns. Essentially, the cart needed the ability to turn on a dime as well as crabwalk sideways by turning all of the wheels in the same lateral direction. The cart required four different steering modes—an impossibility with conventional mechanical linkage."

Control Design

|

|

Peter Nachtwey Named to IFPS Hall of Fame

Delta was pleased to learn that our President, Mr. Peter Nachtwey, was selected as an inductee of the 2020 class of the International Fluid Power Society's Hall of Fame. In his biography, the IFPS cites Peter's application of microelectronics, software, mathematical modeling, and numerical analysis to control theory for industrial fluid power machinery. Peter developed the algorithms that are the foundation for Delta's motion controllers. Peter's interest and passion is making advanced control algorithms for hydraulic systems which result in simpler, faster, more economical, and more precise machines.

Peter has written and presented his results prolifically throughout his career, publishing in numerous technical journals and speaking at conferences throughout the world, including the IFPE, NFPA, FPDA, and FPTC. Peter has also provided technical support and expertise for projects in hydroelectric dam control, food processing, metals processing, test systems, presses, and sawmilling. Many of the lessons he's learned have been collected and published in Delta's Practical Design for Fluid Power Motion Control.

|

|

|

Peter also writes the "Motion Control" feature for Hydraulics and Pneumatics magazine. If you haven't had an opportunity to read Peter's work before, here is the "Motion Control" article published April 2020.

|

|

Distributor Highlight

Since their simple beginnings in 1944 out of a converted Airstream trailer, John Henry Foster of St. Louis, MO has grown into a diverse fluid power and automation integrating distributor. JHF offers industrial customers parts, service, and design expertise in hydraulics, pneumatics, motion control, compressed air, industrial automation, hose, framing, guarding & partitioning. . . the list is extensive. They serve their customers through physical stores, including several satellite locations throughout the Central Midwest, as well as an e-commerce site. In addition to parts sales, JHF also offers vendor managed inventory services, system service, complete system design and integration services, industrial automation and control services, and training. JHF is an authorized Delta RMC distributor, and can integrate the RMC motion controllers into customer's fluid power systems.

Congratulations John Henry Foster on 76 years of industrial fluid power sales and support!

|

|

|

People at Delta

Sam Juvonen - Business Systems Manager

|

|

|

We are glad to welcome Sam Juvonen as Delta's Business Systems Manager. Sam has an extensive background in business applications support for automotive supply chain manufacturers. He holds a degree from the University of Michigan - Dearborn. After school he began working in consulting and full-time business applications developer roles, eventually culminating as the head of the process support technologies team at a major seals and sealings manufacturer in the Midwest.

Sam has immediately put his skills to work at Delta, customizing and improving our business applications software and databases. When not writing and supporting software applications for Delta, Sam is interested in boating, biking, private aviation, radio control airplanes & helicopters, and woodturning. Delta is fortunate to have Sam, with his skills and experience, as part of our team.

|

|

|

|

|

Delta was pleased to sponsor a recent LunchBox Sessions Live in collaboration with FluidPower World. The session, entitled "Servo Valves: Running Live and In 3D," was presented by the CEO of LunchBox Sessions, Carl Dyke. Carl provided viewers with clear explanation of the different kinds of hydraulic servo valves, how they operate, and what they look like inside. Enjoy this recording of the "Servo Valves" session, and see the other recordings in the series at the link below.

|

|

Tech Tip

RMCTools Plot Auto-Saves

by Aaron Heinrich, Marketing Manager

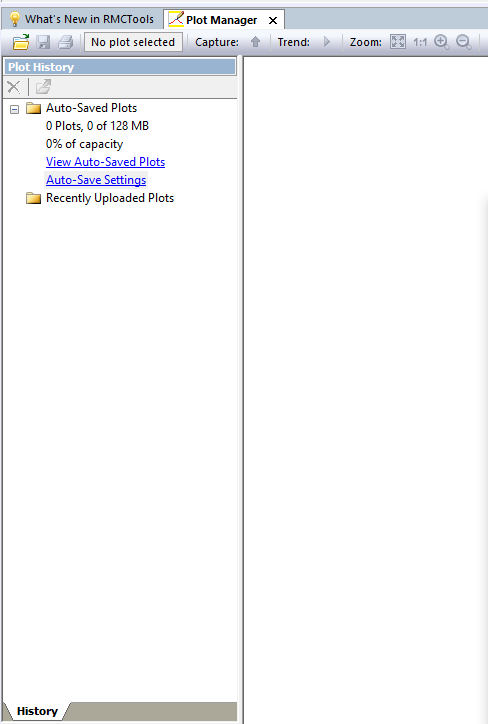

Have you ever closed your RMCTools session, and then the realization dawns on you that you forgot to save the plot files you were gathering from your RMC motion controller? Now you have to start up RMCTools, set up your moves again, and re-create those plots - frustrating and time wasting!

With version 4.14.0 and on, RMCTools automatically caches uploaded plots in an internal folder for later retrieval, in case the user forgets to save the plots to a location on their computer or network. This feature isn't intended to act as an auto-save feature; the user still should save and name plot files to the location of their choosing. But this is a preventative measure to ensure that plot data isn't accidentally lost. Plot Auto Saves are enabled by default, and the feature settings are found in the Plot Manager History tab.

|

|

|

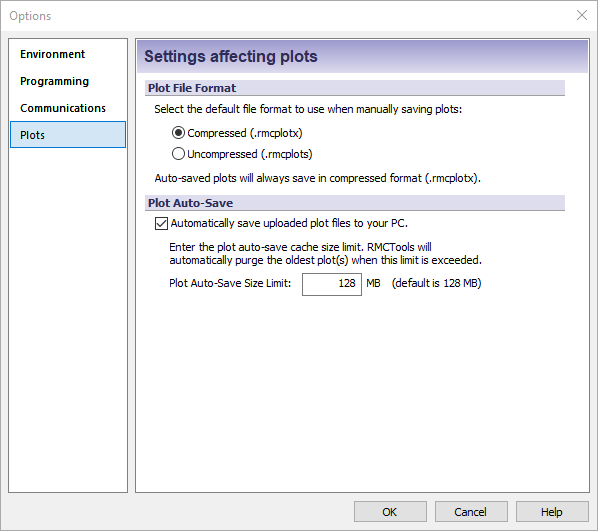

The amount of storage space dedicated to auto-saved plots can be adjusted in the Auto-Save Settings menu. This is the same location where the user can select saving compressed or uncompressed RMC plot files.

Delta offers a number of ways to learn more about RMCTools and RMC Motion Controller features. Delta's website has the RMCTools Online Help, which has a searchable index full of technical information. We also host the Delta Discussion Forum, where RMC users can exchange ideas on implementing applications, Applications Engineers will post code examples, and you can find recommendations from Delta's in-house testing of third-party products that work well for high-performance motion systems.

|

|

Tradeshows & Conferences

Upcoming Trade Shows

With the worldwide COVID-19 outbreak, the trade show outlook is frequently changing. Many shows are choosing to cancel entirely or postpone to dates in 2021. The dates shown are tentatively scheduled at the time of publication. Please check Delta's Trade Shows page frequently for updates to our trade show schedule as they are announced.

|

|

Portland Exposition Center

Portland, Oregon

Sept. 30 - Oct. 2, 2020

The Suburban Collection Showplace

Novi, Michigan

Oct. 27 - 29, 2020

Las Vegas Convention Center

Las Vegas, Nevada

Nov. 18 - 20, 2020

|

|

|

Learning More About Delta

Education & Training

Delta's in-person Classroom Training is now being offered again, following Washington State guidelines for personal protection and social distancing. Self-Paced, Live Online, and Custom trainings are being offered as usual. Please check Delta's Internet Training page frequently for schedule updates and added classes. You may also contact Delta by phone at (360) 254-8688, at technicalsales@deltamotion.com, or reach out to your Regional Sales Manager.

|

|

Self-Paced Learning

Delta also offers self-paced training options, as well.

- Video Tutorials An easy way to get up to speed on the RMC's features with easy to follow video guides.

- Online RMCs Try RMCTools or custom RMCLink programs when you don't have a physical RMC to test with.

|

|

Discussion Forum

Delta's Discussion Forum is a place for users to share ideas about User Programs, unique applications, or third-party equipment that works well with the Delta RMC Motion Controllers.

|

|

Distributor Only Website

If you are a Delta distributor and need a password or user ID, email us or call Delta at (360)-254-8688.

|

|

Delta Computer Systems, Inc. © 2020 Delta Computer Systems, Inc. © 2020

1818 SE 17th St. - Battle Ground, WA USA 98604-8579

P: 360-254-8688 - F: 360-254-5435

Delta Motion Ltd.

101 Rose Street South Lane - Edinburgh, EH2 3JG, United Kingdom

P: (+44) 0131 447 7924

|

|

|

|