In This Issue...

News

- New Life for An Old Saw

- Knapheide Saves Costs, Time by Moving Vehicle Life Testing In-House

- Precise Pressure and Flow Control Improve Wax Injection

- Multi-Axis Motion Control Streamlines Sawmill Operation

- Knapheide Saves Costs and Time in Nondestructive Vehicle Testing

- Multi-Axis Motion Controller Synchronizes Press Operation

Motion Control Feature

- Using Open-Loop Control for Diagnostics

- Hydraulic Capacitance and Dead Time

- Controlling Hydraulic Pressure

Distributor Highlight

People at Delta

- Fred Babson - Regional Sales Manager

Company News

- Delta European Sales Office

Tech Tip

- Gray vs. Binary Transducer Feedback

Trade Shows & Conferences

Learning More About Delta

- Education & Training

- Useful Links

|

|

|

New Life for An Old Saw

"The effect of machine-component obsolescence can be significant, even if the component itself still functions correctly. Consider, for example, a case where a manufacturer/supplier lacks support documentation, or perhaps its staff at the factory is not available to help. In these cases, it can take a long time to resolve a problem, one that may not have been difficult to deal with when the component was new."

MetalForming, November 2019

|

|

|

Knapheide Saves Costs, Time by Moving Vehicle Life Testing In-House

“The Knapheide Manufacturing Co. has always sent its products out to be tested, but with the wide variety of product types that the Quincy, Ill.-based company makes, the cost of farming out the testing process had become excessive. The manufacturer specializes in the North American utility truck body market, both military and civilian grade, including crane trucks, electrician trucks, and Class 8 heavy-duty truck chassis."

Truck & Off-Highway Engineering, October 2019

|

|

|

Precise Pressure and Flow Control Improve Wax Injection

“In aluminum investment casting, a disposable wax pattern must be made for each part to be formed from molten aluminum. To make those wax patterns, low-temperature paste wax is injected into cavity molds. To get a high-quality pattern, the cavity must be completely filled so that no air is trapped in the mold, which leaves a bubble or void in the final pattern. Therefore, the flow of paste wax must be controlled so entrapped air can escape through vents in the mold."

Machine Design, November 2019

|

|

|

Multi-Axis Motion Control Streamlines Sawmill Operation

“Today’s sawmills are hotbeds of motion control. Modern integrated saw lines rely on coordinating the motion of dozens of moving parts to maximize productivity. For example, AMS Solutions, of Enderby, B.C., Canada, designs customized automation solutions for sawmills across North America. Experts at AMS recently completed the design and installation of a new canter profiler gang saw in a dimensional-lumber mill in the Northwestern U.S. The system AMS installed incorporates 26 hydraulic motion axes being managed by a Delta Computer Systems RMC200 motion controller."

Hydraulics & Pneumatics, December, 2019 |

|

|

Knapheide Saves Costs and Time in Nondestructive Vehicle Testing

“The Knapheide Manufacturing Company of Quincy, IL, is a leader in the North American utility truck body market, so when they adopt manufacturing and testing procedures, the industry takes note. “In the old days we would send our products out to be tested to ensure that they met industry certification standards,” said Richard Pelnarsh, Knapheide test engineer, “but that used to be very expensive, and each test could take weeks to complete, impacting our ability to meet our schedules.” More recently, the company has been developing test systems in house, shortening the process and improving their ability to test customized product configurations. A custom test may also be developed when a need arises to recreate a particular set of events a Knapheide product will experience in the field."

Quality Magazine, November 2019

|

|

|

Multi-Axis Motion Controller Synchronizes Press Operation

“Gasbarre Products, Inc. of Dubois, PA makes powder compacting presses in a variety of sizes, capable of exerting compaction forces from 1 to 750 tons. Most of the company’s customers are suppliers to the auto, lawn and garden, hand tool, and recreational vehicle industries. Gasbarre’s presses are used to form complex shapes from metallic and ceramic powder compounds, which are hardened through a high-temperature sintering process after forming."

Hydraulics & Pneumatics UK, Nov/Dec 2019

|

|

|

Distributor Highlight

Zemarc's motto is "Powerful Ideas Start Here," and since 1976, they have been providing customers with strong technical sales and service. Headquartered in Los Angeles, Zemarc has three other offices across California to conveniently serve their customers. Zemarc is a full-service Parker distributor, providing access to a complete range of fluid power components, products, and services. Their engineers provide design, integration, and support services for custom systems and projects throughout California and Arizona, including integration of Delta's RMC Motion Controllers into new and retrofit applications.

See Zemarc's webpage for a description of their complete linecard, and contact information for all of their locations.

|

|

|

People at Delta

Fred Babson - Regional Sales Manager

East Central U.S., Eastern Canada

We are happy to announce that Fred Babson, CFPS, has joined Delta Computer Systems as a Regional Sales Manager. Fred is assuming the territory and responsibilities of Bruce Coons, who has retired from Delta after 14 years of service. Fred has a vast wealth of experience in fluid power distribution in Central Ohio. Most recently, Fred was the Industrial Products Manager at Scott Industrial Systems, and has been responsible for a wide variety of hydraulic system design work for Scott.

Fred has already been busy traveling his region and visiting the Delta distributors throughout the Northeast and Canada. Fred has also represented Delta at the ICUEE in Kentucky and FABTECH in Chicago in the past few months. Welcome to Delta Computer Systems, Fred!

|

|

|

Company News

Delta European Sales Office

Delta Computer Systems has established a sales office to serve our customers in the European market. The sales office, Delta Motion Ltd., will operate as a wholly owned subsidiary of Delta Computer Systems, Inc. and is located in Edinburgh, Scotland. This office will provide support and training as well as sales and marketing services for Delta in Europe.

Customers can contact Delta Motion, Ltd. with the following contact information:

Delta Motion Ltd.

101 Rose Street South Lane

Edinburgh, EH2 3JG

United Kingdom

(+44) 0131 447 7924

|

|

|

Tech Tip

We are introducing a new segment in Delta News, where our Applications and Design Engineers can share short tidbits of information about RMCs or RMCTools that may not be well known. We hope that Tech Tip will be helpful, and to possibly expand the feature a bit more in the future.

Diagnosing Gray Code vs. Binary Code Transducer Feedback

by David McNichol, Applications Engineer

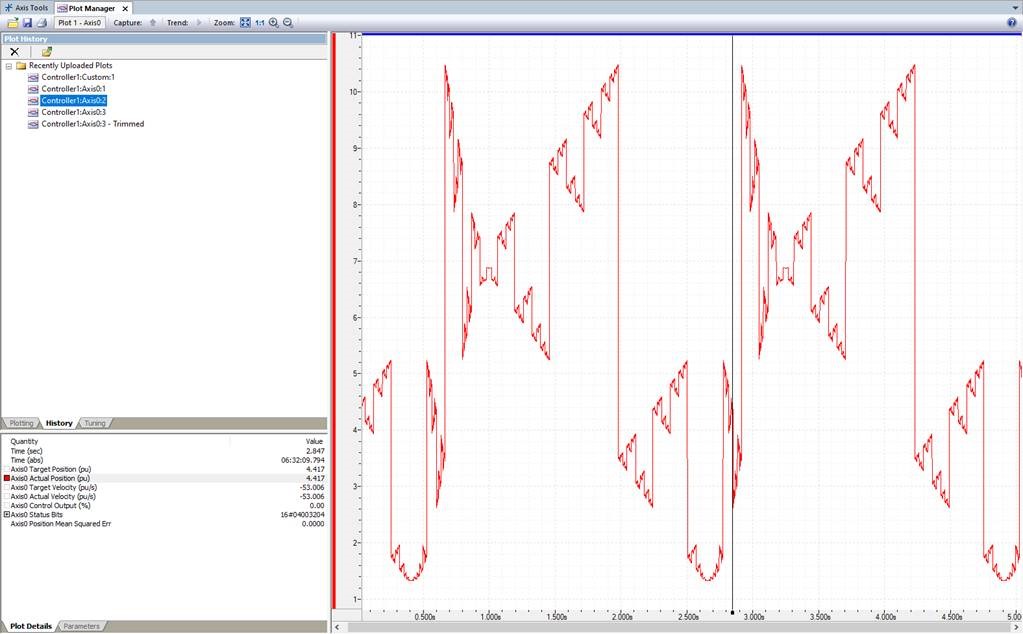

Feedback issues can be difficult to deal with. The RMCTools plotting function is always our go-to method of tracking down an issue. When you see this jagged shape to the SSI feedback, similar to the plot below, it isn't noise or a transducer issue, the feedback is just mis-configured!

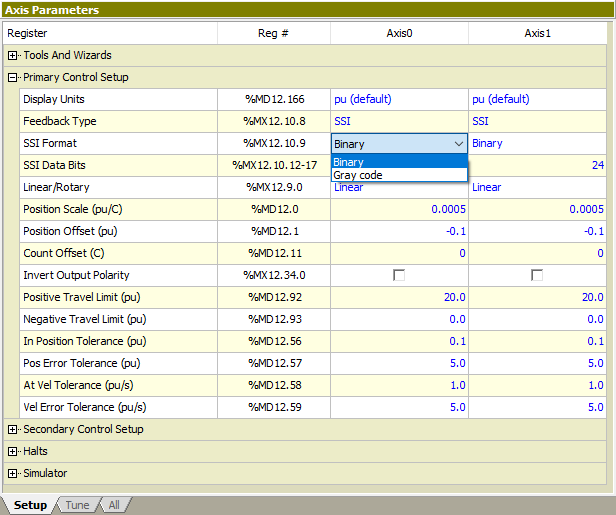

The settings for the SSI Format are found in the Axis Parameters, and can be changed on either the 'Setup' or' All' tab. By changing the SSI format from Binary to Gray code, or vice versa. . .

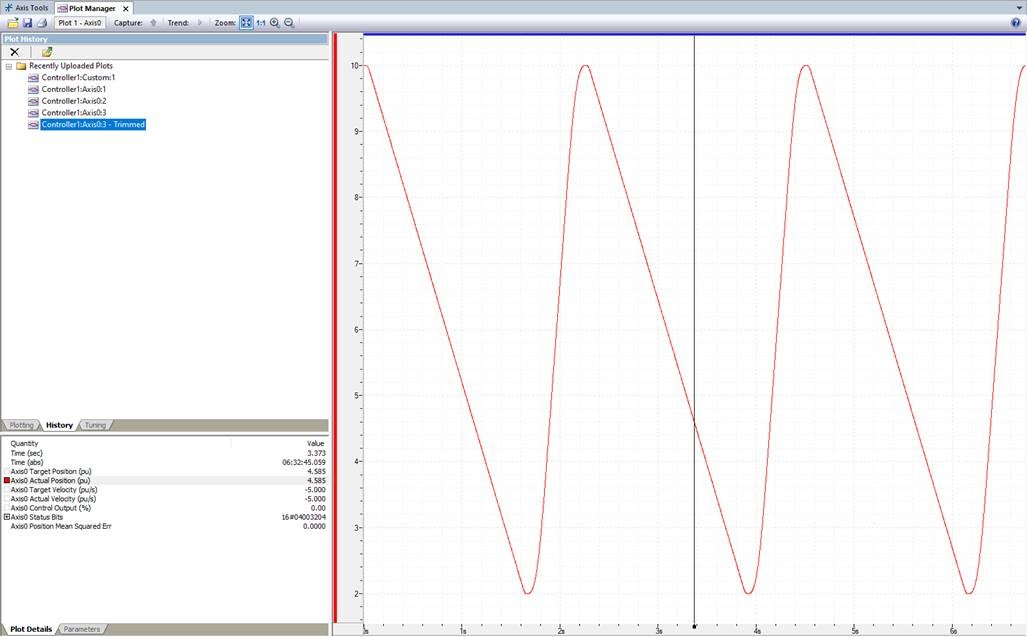

. . . we are able to correct the problem, and now we see a clean feedback signal from the SSI transducer, just as we would expect to see.

Delta has a number of ways to learn more about RMCTools and RMC Motion Controllers features. Delta's website has the RMCTools Online Help, which has a searchable index full of technical information. We also host the Delta Discussion Forum, where RMC users can exchange ideas on implementing applications, Applications Engineers will post code examples, and you can find recommendations from Delta's in-house testing of third-party products that work well for high-performance fluid power systems.

|

|

|

Tradeshows & Conferences

Upcoming Trade Shows

It has been great to meet Delta RMC users and potential new users across the country this year. There are more opportunities to meet and talk with members of Delta’s Technical Sales and Support team throughout 2020.

Please join us! See Delta RMC products and talk with our team at the following locations.

|

|

|

Exibit by ServoControls India

CTC Complex

Chennai, India

Jan. 22 - 24, 2020

Las Vegas Convention Center

Las Vegas, Nevada

Mar. 10 - 14, 2020

Charlotte Convention Center

Charlotte, North Carolina

Apr. 21

NEC Birmingham

Birmingham, UK

Apr. 21 - 23, 2020

Elima Fairground

Jönköping, Sweden

May 12 - 15, 2020

|

|

Long Beach Convention Center

Long Beach, California

May 18 - 20, 2020

Portland Exposition Center

Portland, Oregon

Sept. 30 - Oct. 2, 2020

Svenska Mässan

Gothenburg, Sweden

Oct. 6 - 8, 2020

The Suburban Collection Showplace

Novi, Michigan

Oct. 27 - 29, 2020

Las Vegas Convention Center

Las Vegas, Nevada

Nov. 18 - 20, 2020

|

|

|

Education & Training

Delta offers a variety of different ways to become familiar with the RMCTools software and how to use it to connect, control, & optimize your system. Here are the upcoming training options in early 2020.

| |

|

RMCTools Technical Training

Feb. 11 - Feb. 12, 2020

Apr. 7 - Apr. 8, 2010

|

|

RMCTools Technical Training

Jan. 28 - Jan. 29, 2020 (Battle Ground, WA)

Apr. 1 - Apr. 2, 2020 (Battle Ground, WA)

|

| Sign Up |

Sign Up |

| |

|

|

Delta also provides self-paced training, check out some of these options:

Video Tutorials An easy way to get up to speed on the RMC's features with easy to follow video guides.

Online RMCs Try RMCTools or custom RMCLink programs when you don't have an RMC to test with.

|

Advanced Technical Training

Apr. 28 - Apr. 30, 2020 (Battle Ground, WA)

Sign Up

Please check the Training page frequently as new dates for Advanced Training are added for 2020.

|

|

|

|

|

|

Discussion Forum

Delta's Discussion Forum is a place for users to share ideas about User Programs, unique applications, or third-party equipment that works well with the Delta RMC Motion Controllers.

|

|

Distributor Only Website

If you are a distributor and need a password or user ID, email us or call Delta at (360)-254-8688.

|

|

Delta Computer Systems, Inc. © 2019 Delta Computer Systems, Inc. © 2019

1818 SE 17th St. - Battle Ground, WA USA 98604-8579

P: 360-254-8688 - F: 360-254-5435

|

|

|

|